Last we left off, we had just received the Voodoo Vintage MK50 Hardtail Kit for the 1980 Shovel. We stripped the bike down and took it over to OC Sandblasting where Paul and the crew took it in and handed it back all clean of the paint. They were careful around the already faint VIN stamped on the neck.

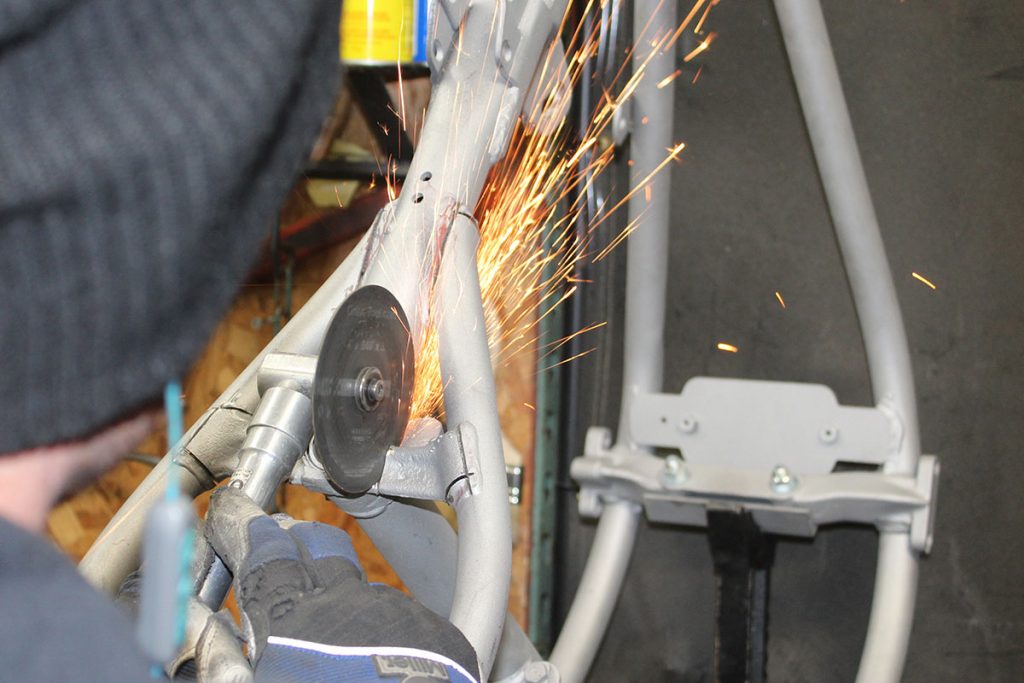

Back at Cambra Speed Shop, Ron Cambra’s expert welder Devin Tobin nervously started to chop the frame to the clear specifications laid out by Michael at Voodoo Vintage. Ron suggested we cut it just a bit short on the lower part of the frame to fit it first citing that it is easier to cut more if need be, than the opposite. We did that, and found that as we were being careful, the directions were correct to cut the frame 2″ in from the centerline of the rear trans mount cross member.

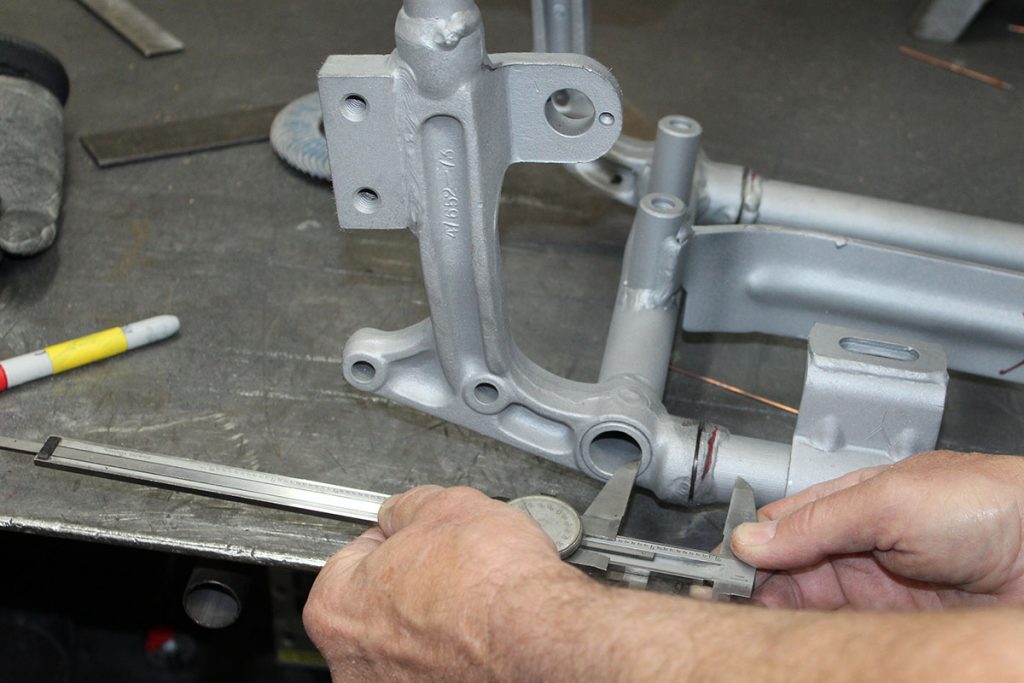

Fabricator and Engineer, Gregg Petersen gave us a tip on scribing a straight line on tube or round stock. Put a hose clamp around it and cinch it up tight and you will have a precise edge to scribe all the way around the bar material.

After it was all cut up per the Voodoo Vintage directions, we decided to clean up some of the other tabs and bungs that we may not be using. Now it is time to start welding. Devin took his TIG rig and got busy. First he spot welded on one side of the top and we took a level to check for square and plumb. Ron suggested we do some plug welds on the bottom of the frame to make it stronger yet. It’s like watching a magic trick as Devin quietly puddied up the frame with his welder. Devin also cleaned up some of the stock welds and went over them with the TIG.

I can’t help to think about my Merciful Car Club buddy Jeff as he said keep everything you cut off. You never know, someone might want to return a hardtail bike back to a swing arm. Yeah, I don’t see that happening. So we plan to do something with the rear end of the original frame, maybe use it as a base for a side table in the studio.

The frame looks freakin’ sick! Completely changes the look of the bike from the get-go. It is stretched 3.75″ back and lowering the frame 2.75″.

Next up is to cut up the donated front end so the bike sits level. Watch for that story soon!