Here’s one from the archives. Originally posted August 2008. Story/Photos – T-Bone

I recently picked up some cool goodies from Edelbrock. My old chrome valve covers and ubiquitous air cleaner had to go. My 390 powered ’56 Fairlane is in for an engine compartment clean-up so I picked some Classic Style finned valve covers (part # 4162) ,matching air cleaner (part # 4117), and a Victor polished breather (part # 42133).

My buddy Tim came over to give a hand at this rather simple job. Gold Dust came over a bit into the job and re-affirmed that this is a 3 beer job on his beer scale of difficulty. His Beer Scale of Difficulty gets exponentially larger as you move on to more difficult duties. The more beer you drink the more difficult that task becomes. More on that later. Now to the job at hand.

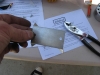

Out with the old – in with the new-old. The ’56 is sporting a 390 with an Edelbrock Performer RPM intake with GT Heads taken from a ’68 Thunderbird back in the day. We removed the old thin chrome steel stamped valve covers, cleaned the gasket materials left on the heads with an emery cloth being careful not to get the material in the heads. We had to trim the Edelbrock Valve Cover Gaskets a bit to fit the new sand-cast valve covers and then treated them with some Gasgacinch gasket sealer. When properly trimmed we spread a bit of Permatex Clear RTV Silicone adhesive sealant on the valve covers so the gaskets don’t slip around too much while installing. Tim added a dab of silicone also to the head to intake manifold gap to keep it free from leaking. A dab on the cover bolts hold them in place too.

While we were at it I added a couple of wire looms to keep the spark plug wires in place. We secured the valve cover with the top center bolt then added the rest skipping a hole and going around to all five on each side before tightening them all down. Next was a lunch break. We made sandwiches and ate them out back by the pool before we started with the air cleaner.

Sam rolled up as we finished lunch and he helped with the air-cleaner. And now there’s another pair of hands under the hood. The air cleaner is a bit different than most, it doesn’t employ a nut on top of the air cleaner cover. The lid gets clamped down from the bottom as two threaded rods from the lid go through holes in the front and back of the base plate. However, this Holley carb has a big box in front and the knurled nut won’t fit. I guess that’s why the cleaner came with some extra nuts. A lock washer from my jar of washers and the supplied nut secured the front of the cover. The back was a bit of a trick since you are reaching around the carb and trying to thread it without looking and upside down at that. After getting my bearings it went on with a twist.

A quick polish to rid our greasy hand prints and the finished product is really sweet. Now I got to cleanup the firewall and the rest of the engine compartments.