Installing an SQR Performance Ignition Kit on a 327 SBC.

Fellow Mercifuls Car Club member Travis received his dad’s first year 327 equipped Camaro. He said this car has a checkered history for him. Every time he was there to help his dad out on the car, it always bit him. The last bolt that strips, the wrecked knuckles, chasing that electrical gremlin, the splash of hot motor oil, you know the usual stuff when working on these old cars. His dad cherished the car. It isn’t a showstopper, it is a car that was comfortable for the old man. Now it’s Travis’ turn with it. One of the first things to tackle in making it a bit more reliable is the ignition system.

I met up with Cole from Flex-A-Lite at the recent SEMA MPMC Media Conference and he told us about their new line of performance ignition products called SQR Performance; Superior product; Quality that you can see, feel and experience; and Reliability that you can count on. They had an HEI Distributor and Spark Plug Wire set perfect for this Hand Me Down Camaro project.

What better way to start a new life of memories with the car than in the driveway, on a Sunday with a bunch of buddies stopping by to lend some help, or just stand and watch the action. Eric, a seasoned mechanic and painter rolled over on his kid’s minibike and Ken took a long stroll from across the street to see what all the fuss was about.

A fairly simple project to stab the new HEI Distributor into the block and string up some new plug wires to the cylinder. I joked with Travis, is this going to be a 2 or 6 beer job? He said with this car, it’s up in the air.

So, let’s get down to it. The installation of a distributor can be rather daunting to some. Travis and his buddy Eric are rather adept at it. They have been goofing around with cars for quite a while and they want to share some tips with you.

Get to TDC, that’s top dead center. Before you remove the old distributor, take off the cap and not where the rotor is pointing. Then turn the crank with a wrench on the pulley to get the rotor pointing in the cylinder number 1 position. Then check the timing marks on the drive pulley. It should be close to the TDC mark, you may have to advance or retard it a bit to get right in line with the stationary mark. Another tip is to pull the plug off cylinder #1 and rotate the crank till you feel the piston at the very top of the stroke. With a 4-stroke engine, there is a compression stroke, so be sure the timing mark is at the TDC mark on the pulley. Before you stab the distributor, Eric suggests adding a touch of assembly lube to the gear, just to make sure there is proper lubrication.

Another tip is to know that the distributor rotor will turn as you remove the distributor, that is the gear moving as it is pulled. The rotor will turn again when you install the new distributor. Make note of the change and watch as it turns when you go back in. If the new rotor is not aligned properly your engine will either not turn over or it will run like shi- err crap. There is some wiggle room as you tune the engine by turning the distributor before cranking it down all the way.

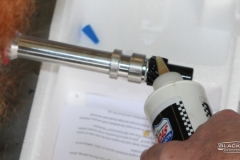

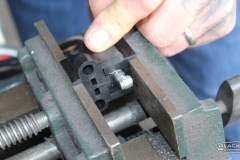

I hope all of you are familiar with installing new spark plug wires. Refer to auto mechanics basics 101 if you need help. The new SQR Performance brand from Flex-A-Lite has some great 8mm and 8.5mm performance wires that promise a great decrease of resistance than the competitors in the marketplace. We went with their 90° plug boot. One of the biggest challenges on installing plug wires is the cutting, stripping, and crimping the terminals. The thick outer casing is easy enough, but there must be special care in stripping down the core, not to cut it. This is where the engineers at SQR Performance came up with a brilliant solution. Simply cut your wire completely, then with their small copper inserts you can insert one end of the copper strips halfway into the end at the core and bend it over the outer wire insulation. Then you just take the terminal and wrap it around that copper strip and wire, crimp it down and insert it into the boot as usual. The wire kit comes with a block crimper to use with a vice. Super easy. Be sure to add a touch of Dielectric Grease inside the boot to make a nice connection to the plug.

After about an hour we were able to turn the key and watch it blow up! Just kidding, it turned over with a roar. We took it for a test drive and the tune was really just right. No pinging when you get on it, smooth idle, really nice. This actually ended up being a No-Beer job! Clearly something we missed. I can honestly say that if you are interested in changing out your ignition system, take a look at SQR Performance a part of the trustworthy Flex-A-Lite family.